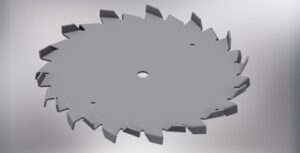

Dispersion blades are critical tools that drive efficiency and consistency across a wide range of industries. Quality dispersion blades from Nowak ensure materials are properly mixed, blended, or dispersed to meet high production standards.

Nowak stainless steel dispersion blades are used in dozens of industrial applications that demand mixing precision and long-term durability.

Paint and coatings manufacturers rely on dispersion blades to evenly mix pigments, while the fields of chemicals and petroleum use them to blend additives and compounds to produce reliable formulations. Asphalt companies use them to maintain uniformity in construction materials.

Paper mills, recycling facilities, and even cosmetic manufacturers depend on precise dispersion blades, whether it’s breaking down pulp for paper production, processing recovered materials, or blending a diverse range of ingredients into cohesive mixtures for personal care products.

From industrial plants to everyday consumer products, dispersion blades are a crucial component in achieving precise, reliable mixing results. For decades, mixing specialists have relied on OEM blades supplied by the manufacturer of their specific mixing machines. While many businesses routinely reorder dispersion blades from an original equipment manager, this approach can lead to a number of operational challenges:

- Higher Costs – Costs of blades add up quickly, especially for industries mixing highly abrasive materials that require more frequent replacement.

- Slow Lead Times – OEM dispersion blades, particularly those in less common sizes, often require long manufacturing and shipping timelines that can disrupt tight production schedules.

- Limited Availability – Certain blade sizes and configurations are not always readily available, which can make them difficult to source quickly and cost-effectively.

Industrial Dispersion Blades Replacements from Nowak

Nowak Industrial Products uses proprietary manufacturing methods to produce high-quality dispersion blades at a better price than OEMs.

Nowak Industrial Products first began manufacturing dispersion blades over 10 years ago while working with Vance Brothers, a long-time client in the asphalt and construction material industry. That company was facing a set of challenges familiar to many manufacturers – increasing prices and long lead times that were slowing down materials production.

Nowak Industrial Products had the solution for them. Nowak went to work designing and then manufacturing blades that matched or exceeded OEM specifications in quality, performance, and reliability. And with in-house manufacturing, Nowak had the ability to supply blades in the necessary size and material that customers required faster, more reliably, and at a lower cost.

The benefit of Nowak dispersion blades is their consistent performance, readily available supply, and exceptionally good pricing. With Nowak, customers don’t need to choose between cost and quality. Nowak dispersion blades are priced competitively thanks to in-house production, so customers don’t sacrifice performance or risk downtime.

The consistency and precision of Nowak-manufactured blades assures performance at the same high standard that companies expect from the original manufacturer – while in-house production at Nowak provides the reliability needed to keep production on schedule.

Dispersion Blades for Every Industry

Dispersion blades play a critical role in an immense range of industries. Their versatility makes them indispensable in both traditional and unconventional applications.

Industries that rely on Nowak dispersion blades include:

- Paint & Coatings

- Chemicals & Petrochemicals

- Food & Beverage Production

- Agriculture & Fertilizers

- Asphalt & Aggregates

- Paper & Pulp

- Recycling & Waste Processing

- Cosmetics & Personal Care Products

- Ceramics & Adhesives

304 and 316 Stainless Steel Dispersion Blades

Nowak’s specialized equipment can manufacture both 304 and 316 stainless steel dispersion blades in a wide variety of sizes and blade configurations.

Nowak manufactures dispersion blades in two primary stainless steel options – 304 stainless steel and 316 stainless steel. Each provides distinct advantages based on the operating conditions and materials being processed.

304 stainless steel is the standard dispersion blade material used in most applications. For typical industrial environments, it offers reliable strength, durability, and resistance to corrosion. 304 stainless steel is ideal for mixing paints, coatings, soaps, and many other materials that do not contain any highly corrosive or acidic components.

316 stainless steel provides enhanced corrosion resistance for more demanding industrial environments. This includes acidic, salty, or sulfur-based solutions often found in fertilizers, specialty chemicals, or certain food products. The upgrade to 316 stainless steel can significantly extend the lifespan of the dispersion blades used in these harsher settings and reduce the frequency of replacement.

Make The Switch to Nowak Industrial Dispersion Blades

Reliable performance doesn’t have to come at a premium. By offering quality, cost-effective alternatives to OEM dispersion blades, Nowak Industrial Products helps businesses maintain smooth operations without overspending. With Nowak dispersion blades, companies can optimize their efficiency, reduce downtime, and tackle both standard and unconventional mixing challenges with ease.

For more information on Nowak Dispersion Blades, please call (816) 228-0947 or click here to send the team a message online.